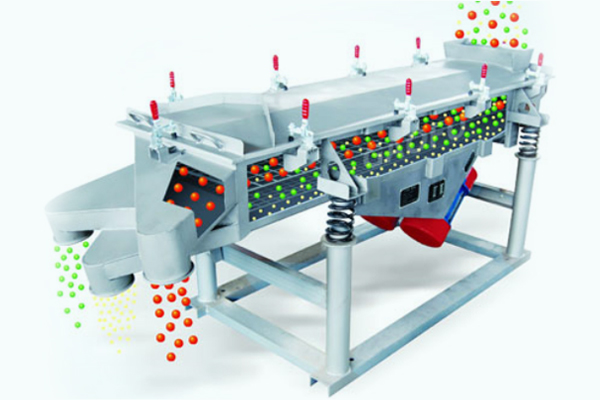

Vertical spiral conveyor's drive motor installed in the lower part of the delivery tower, two sets of vibrating motor symmetrical cross installation, the delivery tower by the pipe and welded pipe around the spiral groove, the delivery tower seat on the damping device. The vibration device consists of base and vibration isolation springs. When the vertical spiral conveyor work, according to the principle of self-synchronization of double vibration motor, the vibration motor generates excitation force, forcing the entire transmission tower for horizontal circular motion and upward vertical movement of the composite space vibration, spiral groove material by the trough of the role of uniform throwing round motion, along the conveyor tank upward movement, thus completing the material up (or down) delivery operations.